CJX2-F225 High Ampere AC Contactor 225A

Ac contactors – Definition & Types

An AC contactor functions as an electromechanical control device designed to establish or interrupt electrical connectivity between power sources and high-capacity loads. Equipped with integrated voltage transient suppression, these devices provide reliable switching operations in power distribution systems. Their primary applications encompass electrical apparatus control and power network management, particularly for operating industrial-scale loads such as motor drives, thermal regulation systems, and illumination control circuits.

As a standardized switching solution, AC contactors serve as critical interface components between control circuits and power equipment, enabling remote current regulation through low-power signal commands. Distinct from circuit protection devices, contactors maintain closed contacts under normal operation until receiving an open command or fault-induced automatic disengagement, ensuring continuous current conduction during equipment service cycles.

WTAIDQ Contactors

WTAIDQ: Global Leader in Electrification Solutions As an industry frontrunner in power infrastructure and industrial automation, WTAIDQ dominates global markets across high/low-voltage systems, energy transmission networks, and smart distribution solutions. Our core expertise lies in advanced electromechanical manufacturing, delivering an extensive portfolio including:

• Power regulation devices: AC/DC contactors with arc-suppression technology

• Circuit protection systems: MCB/MCCB breakers with precision trip mechanisms

• Ground fault protection: Intelligent earth leakage circuit breakers (ELCB)

• Energy distribution units: Modular distribution boards and busbar systems

• Industrial lighting solutions: High-efficiency luminaires with IoT compatibility

WTAIDQ's integrated solutions encompass engineering design services, custom OEM manufacturing, and intelligent panel building solutions, particularly excelling in motor management systems and critical load protection. Certified to comply with stringent international certifications including IEC/EN 60947, our products demonstrate:

1.50,000+ mechanical operations lifecycle

2.100,000+ electrical endurance cycles

3.<15ms arc extinction capability

4.96%+ conductive material purity

Outperforming industry benchmarks set by Schneider Electric, Lovato, and Phoenix Contact products, WTAIDQ's electropneumatic hybrid contactors achieve 30% higher switching stability and 40% reduced contact erosion through proprietary silver-nickel composite contact technology.

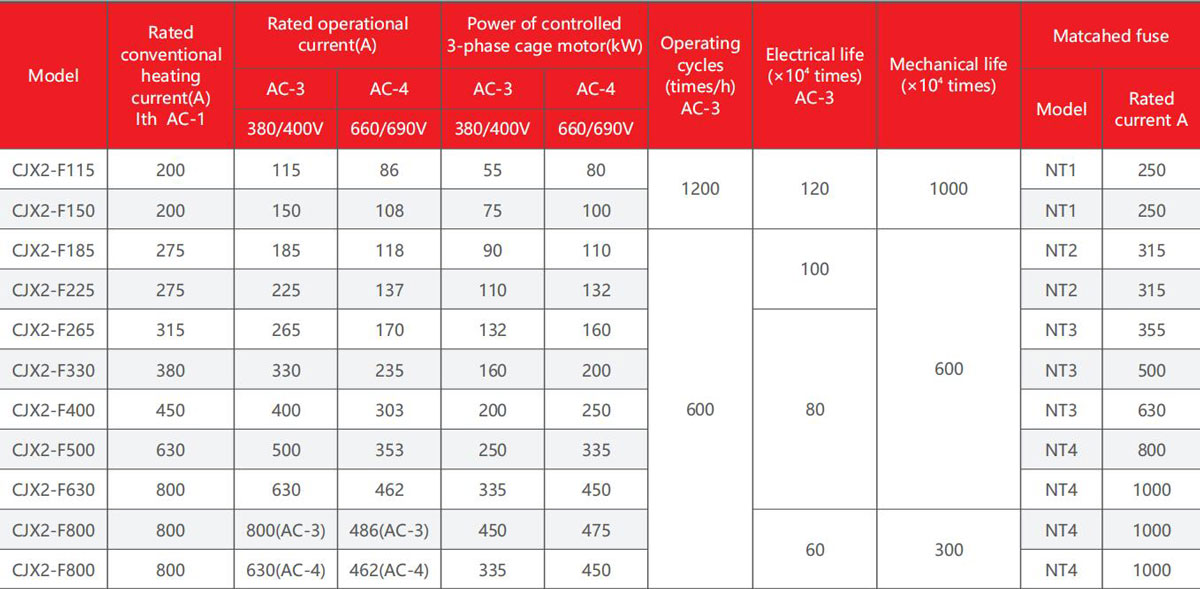

Technical Specification

One of the main features of the CJX2-F225 contactor is its excellent electrical performance. With a rated current of 225A and a voltage range of 660V, the contactor ensures seamless and efficient power transfer regardless of load conditions. Specially designed auxiliary contacts enable the contactor to handle multiple control circuits simultaneously, enhancing its versatility and flexibility in different applications.

Durability and reliability are critical factors when it comes to electrical components, and the CJX2-F225 contactor exceeds expectations in these areas. Constructed from high-quality materials and undergone rigorous quality control testing, the contactors provide long-lasting performance even in harsh operating environments. Its compact and robust construction ensures resistance to shock and vibration, minimizing the risk of damage and downtime.

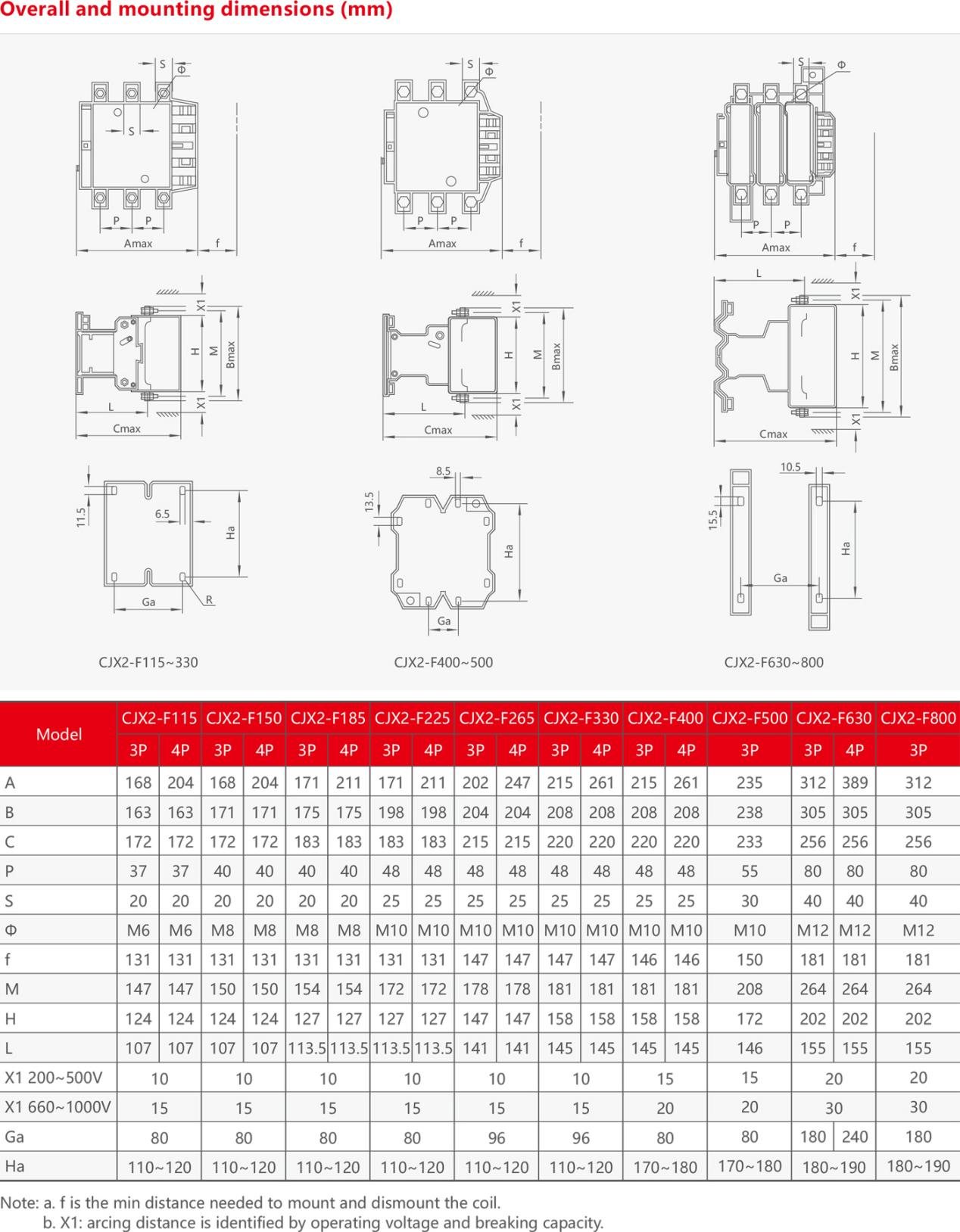

Installation and maintenance are easy and hassle-free thanks to the user-friendly design of the CJX2-F225 contactor. The compact size allows for easy integration into electrical panels, saving valuable space. Front-facing auxiliary contacts simplify wiring, reducing installation time and eliminating the possibility of wiring errors. Additionally, the modular design of the contactors ensures easy access and quick replacement of wear parts, minimizing downtime and maintenance costs.

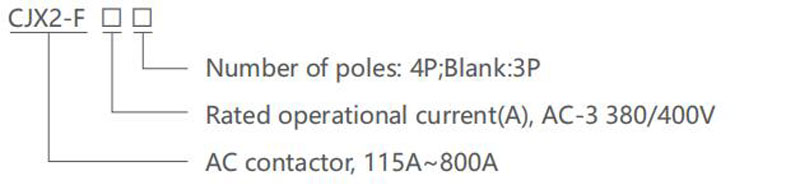

Type Designation

Operating Conditions

1.Ambient temperature: -5℃~+40℃;

2. Air conditions: At mounting site, relative humidity not exceed 50% at the maximum temperature of +40℃. For the wettest month, the maximum relative humidity averaged shall be 90% while the lowest temperature averaged in that month is +20℃,special measures should be taken to occurrence of condensation.

3. Altitude: ≤2000m;

4. Pollution grade: 2

5. Mounting category: III;

6. Mounting conditions: inclination between the mounting plane and the vertical plane not exceed ±5º;

7. The product should locate in the places where there are no obvious impact and shake.

Technical Data

Structure Features

1. The contactor is composed of arc-extinguishing system, contact system, base frame and magnetic system (including iron core, coil).

2. The contact system of the contactor is of direct action type and double-breaking points allocation.

3. The lower base-frame of the contactor is made of shaped aluminum alloy and the coil is of plastic enclosed structure.

4. The coil is assembled with the amarture to be an integrated one. They can be directly taken out from or inserted into the contactor.

5. It is convenient for user's service and maintenance.