CJ19 Contactor for Capacitor Switching 32A

Ac contactors – Definition & Types

An AC contactor functions as an electromechanical control device designed to establish or interrupt electrical connectivity between power sources and high-capacity loads. Equipped with integrated voltage transient suppression, these devices provide reliable switching operations in power distribution systems. Their primary applications encompass electrical apparatus control and power network management, particularly for operating industrial-scale loads such as motor drives, thermal regulation systems, and illumination control circuits.

As a standardized switching solution, AC contactors serve as critical interface components between control circuits and power equipment, enabling remote current regulation through low-power signal commands. Distinct from circuit protection devices, contactors maintain closed contacts under normal operation until receiving an open command or fault-induced automatic disengagement, ensuring continuous current conduction during equipment service cycles.

WTAIDQ Contactors

WTAIDQ: Global Leader in Electrification Solutions As an industry frontrunner in power infrastructure and industrial automation, WTAIDQ dominates global markets across high/low-voltage systems, energy transmission networks, and smart distribution solutions. Our core expertise lies in advanced electromechanical manufacturing, delivering an extensive portfolio including:

• Power regulation devices: AC/DC contactors with arc-suppression technology

• Circuit protection systems: MCB/MCCB breakers with precision trip mechanisms

• Ground fault protection: Intelligent earth leakage circuit breakers (ELCB)

• Energy distribution units: Modular distribution boards and busbar systems

• Industrial lighting solutions: High-efficiency luminaires with IoT compatibility

WTAIDQ's integrated solutions encompass engineering design services, custom OEM manufacturing, and intelligent panel building solutions, particularly excelling in motor management systems and critical load protection. Certified to comply with stringent international certifications including IEC/EN 60947, our products demonstrate:

1.50,000+ mechanical operations lifecycle

2.100,000+ electrical endurance cycles

3.<15ms arc extinction capability

4.96%+ conductive material purity

Outperforming industry benchmarks set by Schneider Electric, Lovato, and Phoenix Contact products, WTAIDQ's electropneumatic hybrid contactors achieve 30% higher switching stability and 40% reduced contact erosion through proprietary silver-nickel composite contact technology.

Short Description

The switching capacitor contactor CJ19-32 is a commonly used electrical device used to control the current switch. It has reliable performance and efficient working ability. The contactor adopts capacitive contacts, which can provide good contact and disconnection functions during current switching. This type of contactor is widely used in various electrical equipment and industrial fields.

The characteristics of CJ19-32 contactor include compact structural design, high temperature resistance, corrosion resistance, reliable contact performance, and long service life. It adopts advanced technology and has high electrical and mechanical stability. At the same time, it also has an overload protection function, which can automatically disconnect the circuit when the current is too high, protecting the equipment from damage.

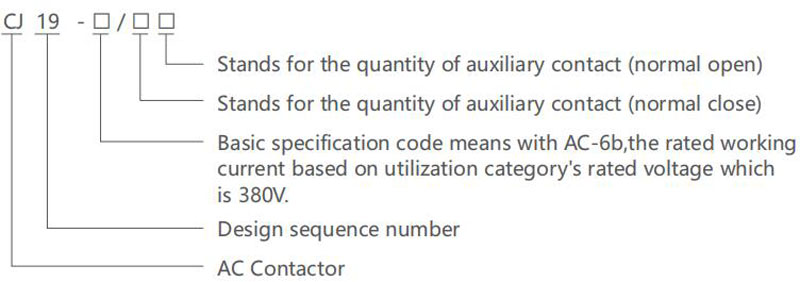

Type Designation

Note:Acquiesce in 3 pairs of N/O main auxiliary contacts and 3 pairs of N/O precharge auxiliary contacts

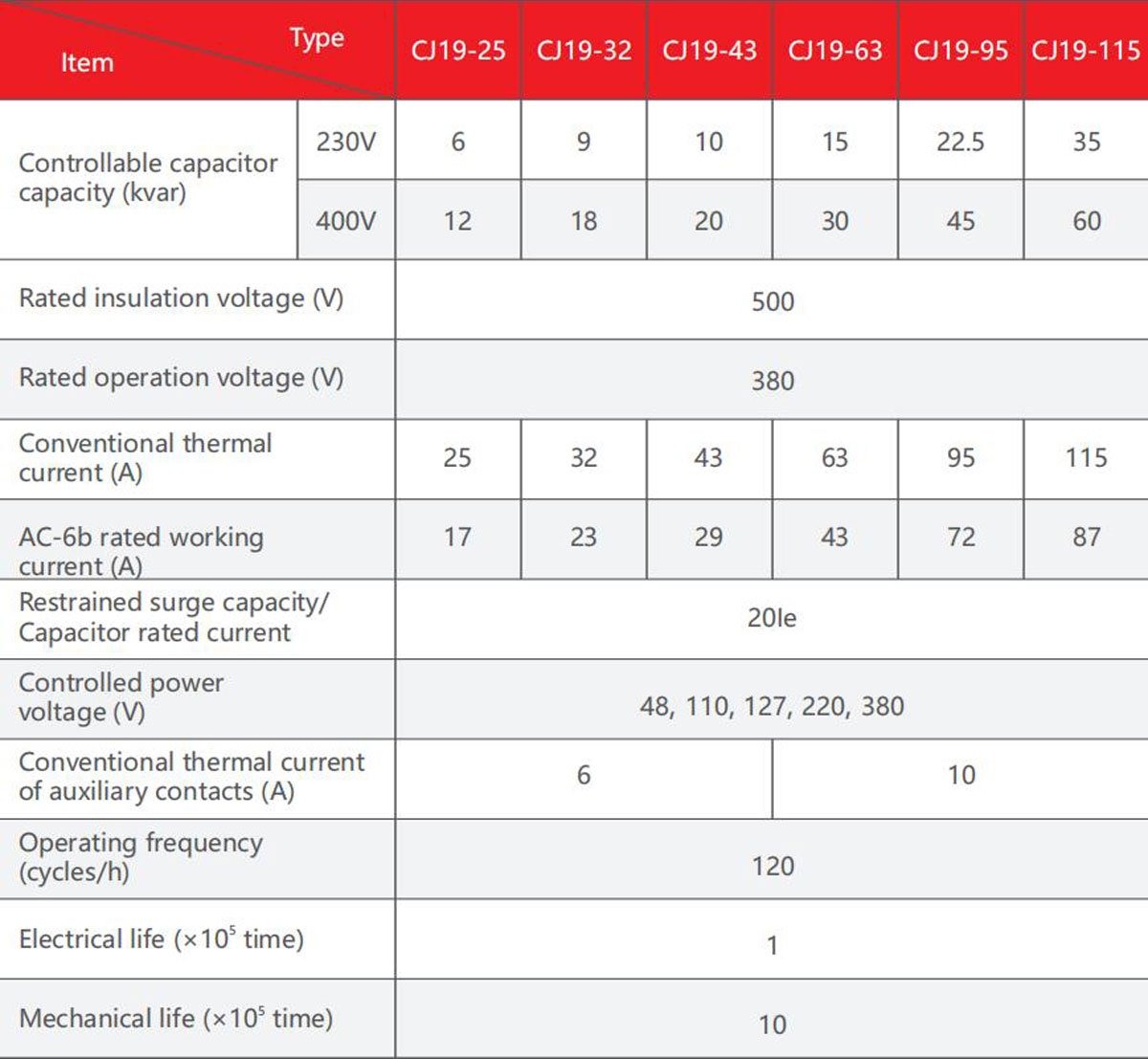

Technical Data

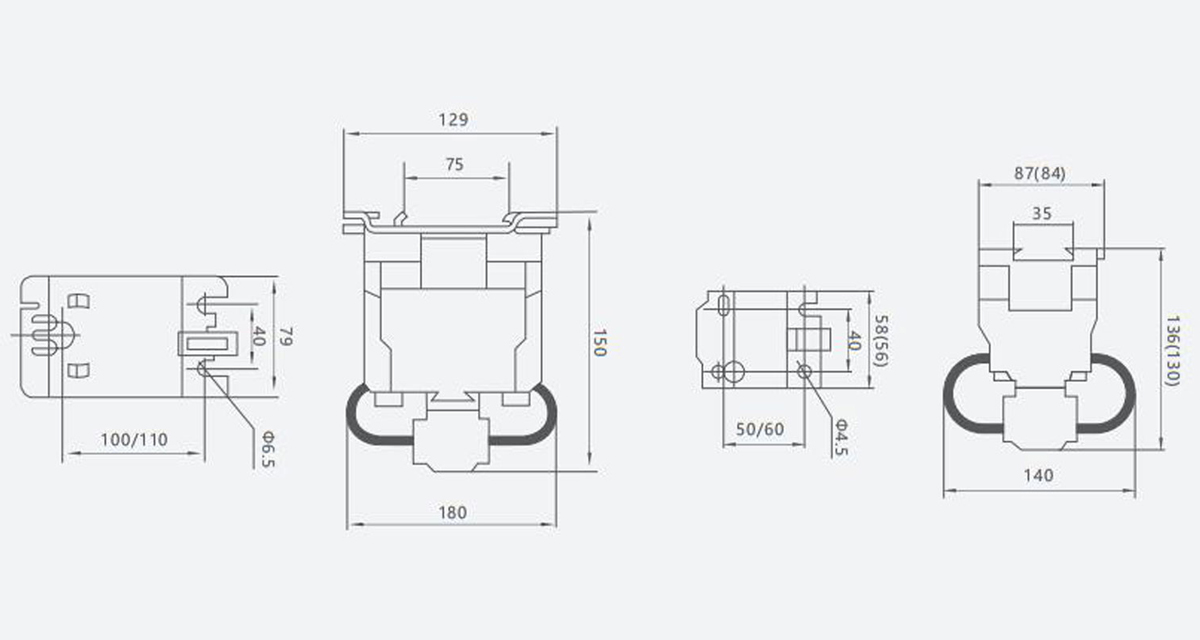

Outline and Installation Dimensions

QC SYSTEM

CE Certification

EAC Certification

ISO9001 Certification

ISO14001 Certification

ISO45001 Certification

World Wide Product Support

During the warranty period, users will enjoy our warranty service through our customer service department, authorized customer service center or your local dealer. WTAI electric also provide extensive post-sale support including maintenance and repair agreements

WTAI has established a complete quality control system.

The entire quality management chain from suppliers to production management to customer experience.

WTAI controls quality from the source through product design.

WTAI emphasizes the construction of quality culture within the company.

WTAI is committed to creating a safe and reliable electricity environment for global customers.

WTAI wants to be the most popular brand in the electrical industry.

FAQ

What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction

Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.