CJX2-4011Z DC Contactor 40A

DC Contactors – Definition & Types

A DC contactor is an electromechanical switching device engineered to manage the connection or disconnection of electrical circuits between DC power supplies and high-current loads. Designed with specialized arc suppression mechanisms, these components ensure safe and efficient interruption of direct current flow, which inherently poses challenges due to the absence of natural current zero-crossings. Their core applications involve controlling heavy-duty DC systems, such as electric vehicle powertrains, battery management systems, renewable energy storage units, and railway traction networks.

WTAIDQ Contactors

WTAIDQ: Global Leader in Electrification Solutions As an industry frontrunner in power infrastructure and industrial automation, WTAIDQ dominates global markets across high/low-voltage systems, energy transmission networks, and smart distribution solutions. Our core expertise lies in advanced electromechanical manufacturing, delivering an extensive portfolio including:

• Power regulation devices: AC/DC contactors with arc-suppression technology

• Circuit protection systems: MCB/MCCB breakers with precision trip mechanisms

• Ground fault protection: Intelligent earth leakage circuit breakers (ELCB)

• Energy distribution units: Modular distribution boards and busbar systems

• Industrial lighting solutions: High-efficiency luminaires with IoT compatibility

WTAIDQ's integrated solutions encompass engineering design services, custom OEM manufacturing, and intelligent panel building solutions, particularly excelling in motor management systems and critical load protection. Certified to comply with stringent international certifications including IEC/EN 60947, our products demonstrate:

1.50,000+ mechanical operations lifecycle

2.100,000+ electrical endurance cycles

3.<15ms arc extinction capability

4.96%+ conductive material purity

Outperforming industry benchmarks set by Schneider Electric, Lovato, and Phoenix Contact products, WTAIDQ's electropneumatic hybrid contactors achieve 30% higher switching stability and 40% reduced contact erosion through proprietary silver-nickel composite contact technology.

Short Description

The DC contactor CJX2-4011Z is a commonly used electrical device used to control the current in DC circuits. It has reliable contacts and highly reliable breaking ability, suitable for control and protection of various DC circuits.

The CJX2-4011Z DC contactor has the characteristics of small volume and lightweight, suitable for installation in places with limited space. It adopts advanced electromagnetic system design, with lower energy consumption and longer electrical life, and can work stably and reliably.

This contactor has a rated current of 40 amperes and a rated voltage of 11 volts. It uses a DC power supply and can operate normally in high pressure and temperature environments. It also has overcurrent, overload, and short circuit protection functions, which can effectively protect the safe operation of circuits and equipment.

CJX2-4011Z DC contactors are widely used in industrial automation control fields, such as power systems, steel metallurgy, petrochemical, mechanical manufacturing, etc. It can be used in conjunction with other electrical equipment and controllers to achieve automated control and monitoring of circuits.

In summary, the CJX2-4011Z DC contactor is a high-performance and reliable electrical equipment suitable for the control and protection of various DC circuits, providing important support for industrial automation control.

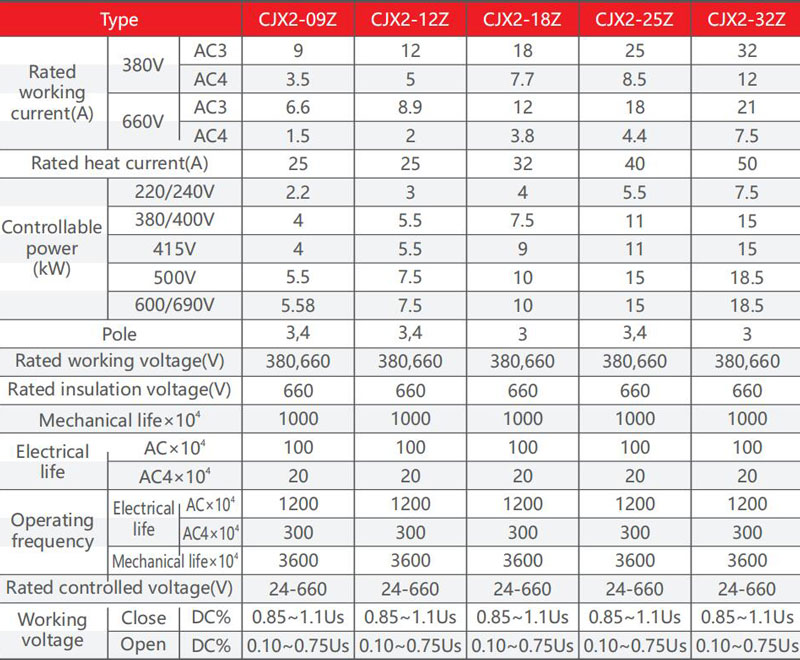

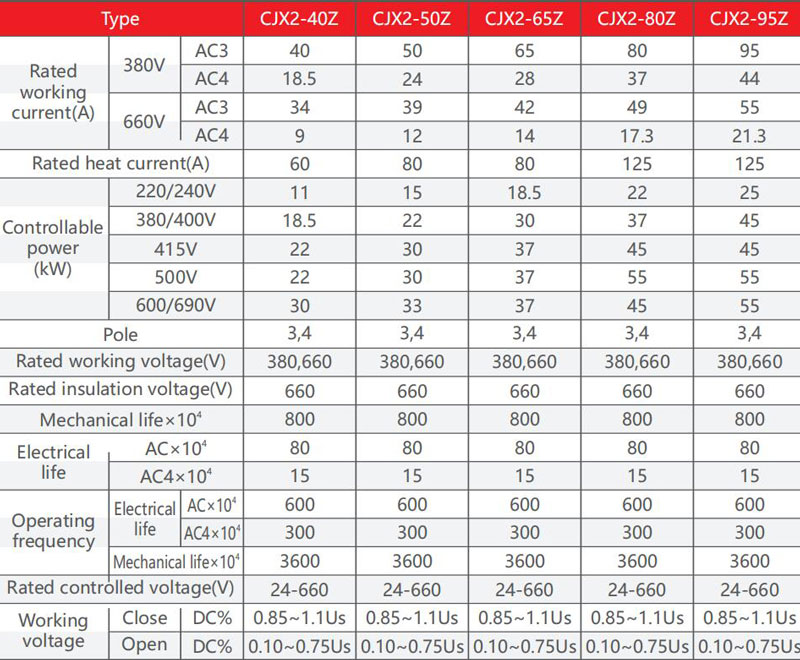

Specifications

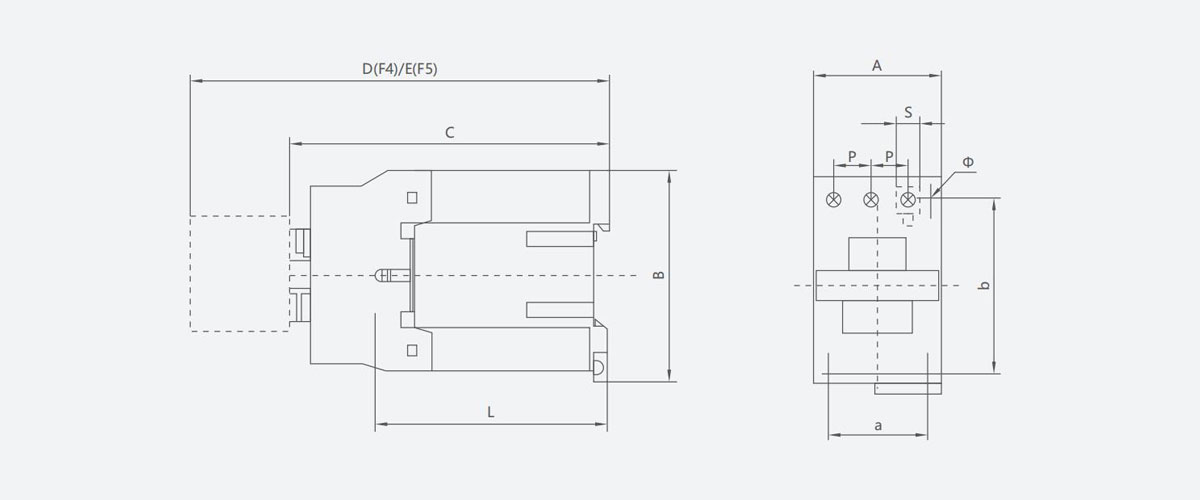

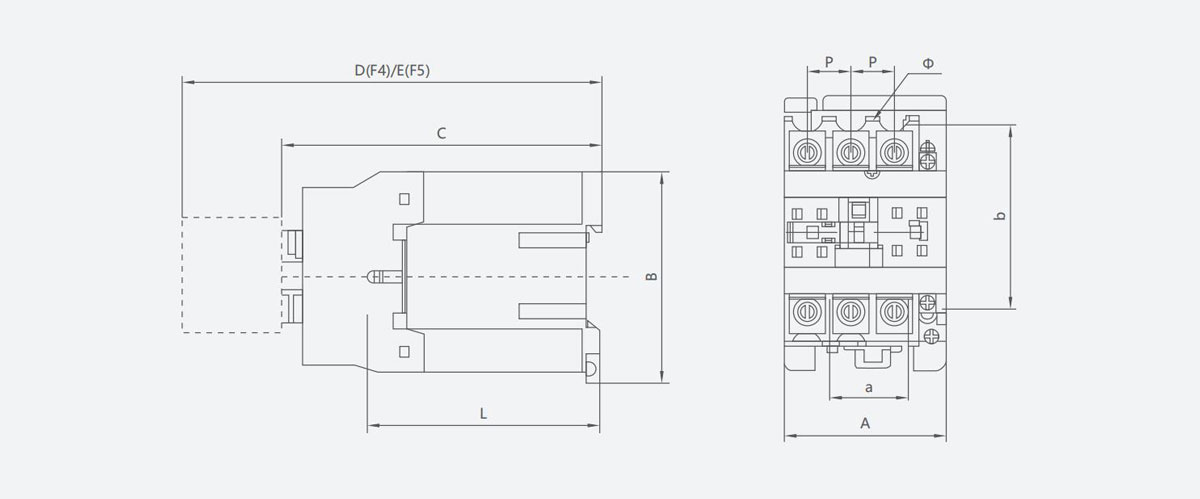

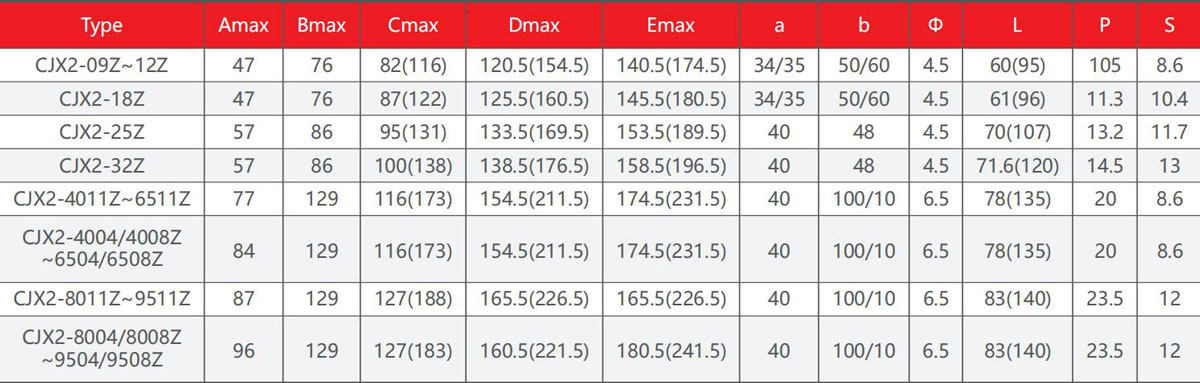

Outline and Mounting Dimension

P1.CJX2-09~32Z

P2.CJX2-40~95Z

The ambient air temperature is: -5C+40°C.24hours its average does not exceed +35°C

Elevation: no more than 2000 meters.

Atmospheric conditions: At +40 when the relative humidity of not more than 50%. at a lower temperature can have a hicher relative humidity, the wettest month average minimum temperature does not exceed +25°C the average monthly maximum relative Humidity doesnot exceed 90%, And consider the occurrence of temperature due to condensation on the product.

Pollution level: 3 level.

Installation category: Ill category.

Installation Conditions: the installation surface and the vertical slope of more than + 50°

Shock Vibration: The product should be installed and used where there is no significant shaking, shock and vibration.