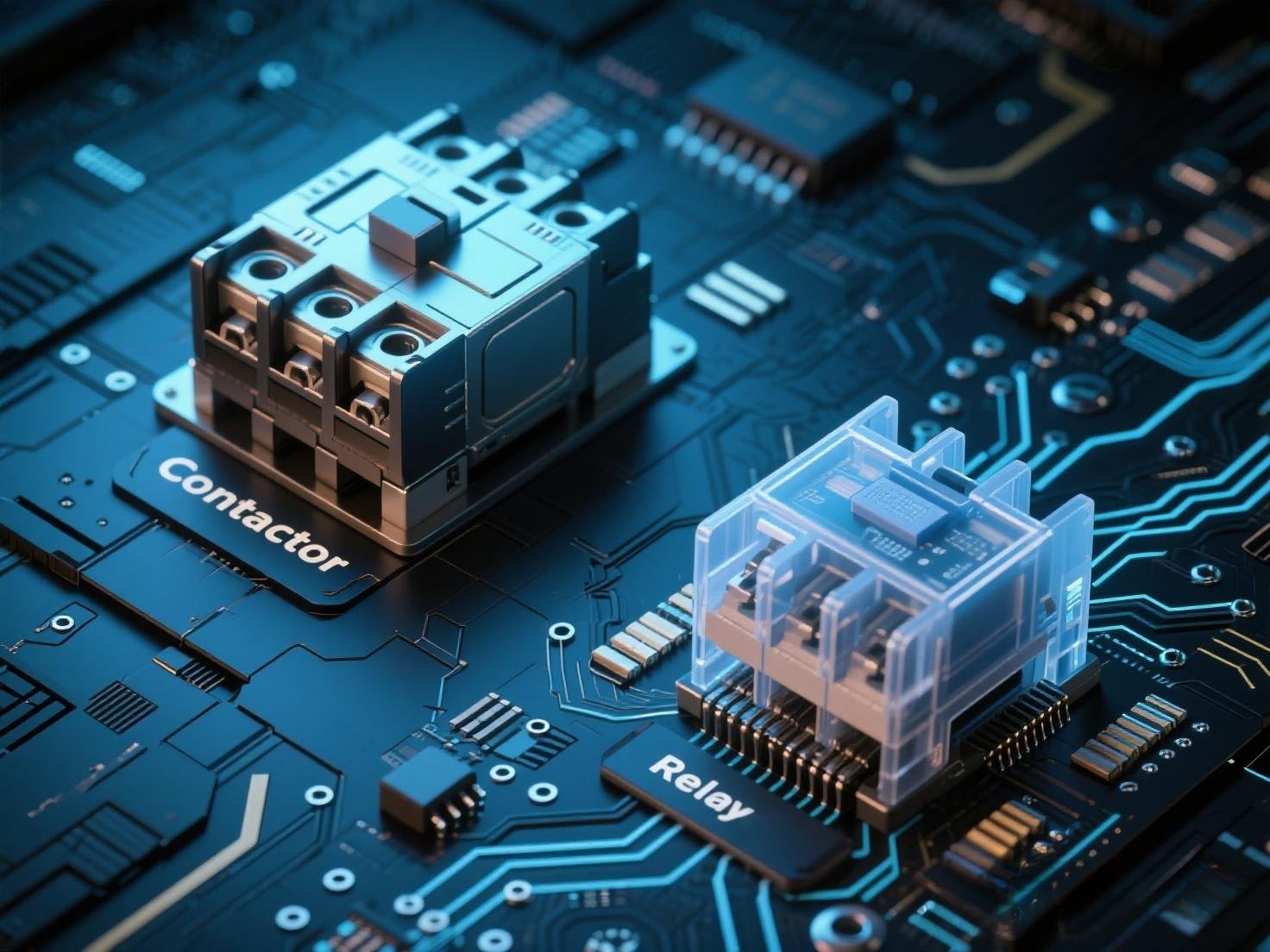

In the world of electrical control, two components stand out for their fundamental role in switching circuits: the contactor and the relay.Choosing the wrong device can lead to premature failure, equipment damage, and, most importantly, serious safety hazards like electrical fires or arc flash incidents.So, how do you decide between them? This guide will break down everything you need to know. We’ll explore what each device is, highlight their crucial differences, look at their specific applications, and give you a clear, step-by-step framework for making the right choice every time.

What is a Contactor?

At its core, a contactor is a heavy-duty, electrically controlled switch designed specifically for high-current applications. Think of it as the muscular workhorse of an electrical system. Its primary job is to safely make and break the connection to powerful loads that draw significant amounts of electricity.

When a small control voltage is applied to its internal coil, it generates a strong magnetic field. This field physically pulls a set of robust, heavy-duty electrical contacts together, completing the main power circuit and allowing current to flow to the load. When the control voltage is removed, the magnetic field collapses, and strong springs force the contacts apart, safely interrupting the current flow.

Contactors are built for endurance and safety. They are designed to handle the high inrush currents of electric motors and the intense heat generated by large lighting and heating systems.

What is a Relay?

A relay is also an electrically controlled switch, but it operates on a much smaller scale. If a contactor is the system's muscle, a relay is its nervous system. It’s designed to switch low-power circuits or to act as an interface between a low-power control signal (like from a PLC or a small sensor) and a slightly larger load.

Like a contactor, most relays use an electromagnetic coil. A small current energizes the coil, creating a magnetic field that moves a lightweight armature, which in turn switches the contacts. The key difference is the scale. Everything is smaller: the coil, the contacts, and the overall physical size.

Relays are perfect for control logic, signal amplification, and switching small loads like indicator lights, small fans, or other control devices. They are not built to handle the physical or electrical stress of high-power applications.

Key Differences Between Contactors and Relays

Now that we have a basic understanding, let's put them side-by-side. While they operate on a similar principle, their design, purpose, and capabilities are worlds apart. I've found that breaking it down into a few key areas makes the distinction crystal clear.

| Feature | Contactor | Relay |

| Current Rating | High (9A to over 1000A) | Low (Typically under 10A-15A) |

| Primary Application | Power Switching (motors, lights, heaters) | Control Circuits (logic, signal switching) |

| Size & Construction | Large, robust, open frame for heat dissipation | Small, often enclosed or PCB-mounted |

| Safety Features | Mandatory arc suppression, spring-loaded contacts | Typically no arc suppression needed |

| Contact State | Main contacts are Normally Open (NO) for safety | Can be NO, Normally Closed (NC), or Changeover |

| Voltage | Handles high voltages (e.g., 480V, 690V, 1000V) | Handles lower control voltages (e.g., 24V, 120V, 230V) |

| Durability | Built for millions of high-power switching cycles | High cycle life, but for low-power loads |

| Cost | More expensive due to size and materials | Less expensive |

Let's dig a little deeper into these points.

● Load Capacity is the #1 Differentiator: Contactors switch amps; relays switch milliamps or a few amps at most. Trying to use a relay to start a 40A motor will instantly weld its contacts together, creating a severe safety hazard.

● Safety is Paramount in Contactors: The inclusion of arc suppression and heavy-duty, spring-loaded contacts is non-negotiable for contactors. The springs ensure that even if the contacts start to weld, they are forced apart when the coil de-energizes. Relays don't handle enough energy to require these features.

● Contactors are Fail-Safe by Design: The Normally Open nature of a contactor’s main contacts is a fundamental safety principle known as "fail-safe." If control power is lost, the device defaults to the 'off' state. Relays in control circuits can be NO or NC depending on the required logic (e.g., you might need an NC contact for an emergency stop circuit).

● Auxiliary Contacts: Both devices can have extra contacts. On a contactor, these are called auxiliary contacts. They are physically linked to the main contacts but are electrically separate and rated for low power. They are used to send a status signal back to a control system (e.g., a "motor running" light) or for "seal-in" logic to hold the contactor energized.

Applications of Relays in Electrical Systems

Because of their low power rating and versatility, relays are found in an incredibly wide range of applications. They are the unsung heroes of automation.

● Control Panels: Relays are the backbone of control logic in industrial panels. They are used to isolate circuits, invert signals, and execute simple logic functions before PLCs became dominant.

● PLC and Microcontroller Interfacing: A PLC or Arduino can't directly power a 120V siren. Their output drivers are low-power. A relay is the perfect interface to take the small signal from the controller and switch the higher-power siren circuit.

● Automotive Systems: Your car is filled with relays. They control your headlights, power windows, fuel pump, and radiator fan. The switch on your dashboard only handles a tiny signal to energize the relay coil.

● Home Appliances: The thermostat in your home uses a relay to turn your furnace or air conditioner on and off. The control board in your microwave uses relays to power the magnetron and turntable motor.

Applications of Contactors in Electrical Systems

Contactors are used wherever serious power needs to be switched, especially frequently.

Motor Starters: This is the most common application. Contactors are the primary switching component in across-the-line starters for three-phase induction motors used in factories, conveyors, and pumps. For these, we often recommend our CJX2-F series, which is built for the rigors of frequent starting and stopping.

Large-Scale Lighting: Think about the lights in a sports stadium or a large warehouse. You can't switch thousands of watts with a simple wall switch. A contactor is used to control entire banks of lights from a single, low-power control signal.

Industrial Heating: Large electric furnaces, ovens, and industrial heating elements draw enormous amounts of current. Contactors are essential for safely controlling the power flow to these high-demand loads.

HVAC Systems: The compressors and large fan motors in commercial air conditioning and heating systems are switched by definite purpose contactors, which are a specialized type built for the demands of HVAC cycling.

How to Choose Between Contactors and Relays

So, you have a circuit to switch. How do you decide? Run through this checklist for your application.

1. What is the Full Load Current (Amps) of Your Device?

This is your first and most important question.

● If the load is less than 10A (and purely resistive): A relay is likely sufficient.

● If the load is greater than 10A, or if it is an inductive load like a motor: You must use a contactor. Always check the motor's Full Load Amp (FLA) rating on its nameplate. It's best practice to select a contactor rated for at least 125% of the motor's FLA.

2. What is the System Voltage and Type (AC/DC)?

Ensure the component's rating matches your system.

● Contactors are rated for high voltages like 480V or 690V AC. There are also specific DC contactors, like our CJX2-Z series, for switching high-power DC loads.

● Relays are typically used at lower control voltages (e.g., 12V DC, 24V AC, 120V AC).

3. Are You Switching a Power Circuit or a Control Circuit?

This simplifies the choice immensely.

● Power Circuit: A circuit that delivers the main operational power to a load (e.g., motor windings). Use a contactor.

● Control Circuit: A circuit that handles logic and signals (e.g., from a sensor to a PLC input, or from a PLC output to a contactor coil). Use a relay.

4. What Industry Standards Must You Follow?

In a professional setting, your components must meet certain safety and performance standards. The two most recognized are:

● IEC (International Electrotechnical Commission): The global standard. Products like our WTAIDQ contactors are certified to standards like IEC 60947, which defines their performance and testing for low-voltage switchgear.

● NEMA (National Electrical Manufacturers Association): The primary standard in North America. NEMA ratings often categorize devices by size and application type, generally making them appear more robust but less granular than IEC ratings. You can learn more at the NEMA.

5. What are the Safety Implications?

Consider the consequences of a failure. For controlling any machinery that could harm a person, safety is the top priority.

● Always use a contactor for motors.

● Ensure your design complies with workplace safety standards, such as those from the Occupational Safety and Health Administration (OSHA), which mandates proper component selection for hazardous energy control.

Conclusion

At the end of the day, the distinction between a contactor and a relay is all about scale. Both are essential tools for electrical control, but they operate in different leagues.

Relays are for thinking. They are the low-power, high-versatility components for logic, signaling, and interfacing.

Contactors are for doing. They are the high-power, high-safety components for switching heavy loads like motors and industrial heaters.

If you're ever in doubt, especially with a critical or high-power application, consulting the manufacturer's specifications and speaking with an expert is always the best path forward.

Frequently Asked Questions (FAQ)

Can I use a contactor instead of a relay?

Yes, you can, but it is usually not practical. A contactor is much larger, more expensive, and consumes more power to energize its coil than a relay. It would be significant overkill for a low-power control circuit.

Can I use a relay instead of a contactor?

Absolutely not. This is extremely dangerous. A relay's contacts are not designed to handle the high inrush current of a motor or the energy of a high-power circuit. Attempting to do so will cause the contacts to arc severely and weld together, meaning you can no longer turn the device off. This creates a serious fire and safety risk.

What do Normally Open (NO) and Normally Closed (NC) mean?

● Normally Open (NO): In the device's default, de-energized state, the contacts are open, and no current can flow. The circuit is completed only when the coil is energized.

● Normally Closed (NC): In the device's default, de-energized state, the contacts are closed, and current can flow. The circuit is interrupted only when the coil is energized.

Are all contactors Normally Open?

The main power-switching contacts of a contactor are designed to be Normally Open for safety. However, the smaller, built-in auxiliary contacts can be a mix of both NO and NC types to provide status feedback to control systems.

Post time: Jun-24-2025